This solid electrolyte can make lithium-air batteries viable and kill lithium-ion batteries

This solid electrolyte can make lithium-air batteries viable and kill lithium-ion batteries

Due to their high theoretical energy density, lithium-air batteries (solid electrolyte can make lithium-air batteries) implemented in an electric car can offer up to 600 kilometers of autonomy with a much lower weight than lithium-ion batteries.

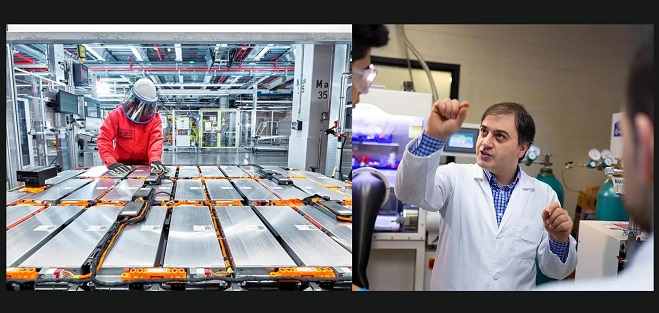

The handicaps that electric cars still have to overcome (charging speed, autonomy, degradation) depend to a large extent on advances in battery development. For now, lithium-ion batteries dominate the world, although several technologies seek to replace them in the future. One of them is lithium-air (or lithium-oxygen), whose energy density can be much higher if some of the barriers that currently prevent them from being technically and economically viable can be overcome.

In a lithium-ion battery (solid electrolyte can make lithium-air batteries), the negative electrode is made of graphite, the positive electrode is made of a metal oxide, such as lithium cobalt oxide, and the electrolyte is a lithium salt dissolved in an organic solvent. The action of the battery depends on the movement of lithium ions between the electrodes. Lithium-ion batteries deteriorate over time and their relatively low energy densities mean they need to be recharged frequently.

Then, for an electric vehicle to perform more on a single charge, it is necessary to make them larger and heavier, and more expensive. A path that is not always the most successful. The other is to increase battery capacity while maintaining volume and weight. This strategy requires rethinking the battery cells and often altering the chemical formula of the electrodes, the electrolyte, or both. Solid-state batteries, for example, have higher energy densities but have very short lifespans.

The challenges of lithium-air batteries

Lithium-air batteries are considered the batteries (solid electrolyte can make lithium-air batteries) of the future. Its theoretical energy density can multiply by ten that of lithium ions. They could offer autonomy of 600 kilometers on a single charge with less weight also offering a longer useful life.

However, the prototypes (solid electrolyte can make lithium-air batteries) created so far only work with pure oxygen, offering a poor performance rate and unwanted chemical reactions, which makes development difficult. Its design involves a lithium metal negative electrode and a non-aqueous electrolyte. These electrochemical cells take advantage of lithium oxidation at the anode and oxygen reduction at the cathode.

Until now, no one has been able to solve the many problems that these types of cells have. They are notoriously unstable because metallic lithium reacts with both moistures in the air and water in the electrolyte. Its efficiency is also very low because the charge and discharge voltage difference is large, which causes power losses.

The perfect formula to overcome difficulties

Scientists at the Illinois Institute of Technology say they have found the formula to make lithium-air batteries commercially viable. Their solution quadruples the power density of today’s best lithium-ion batteries.

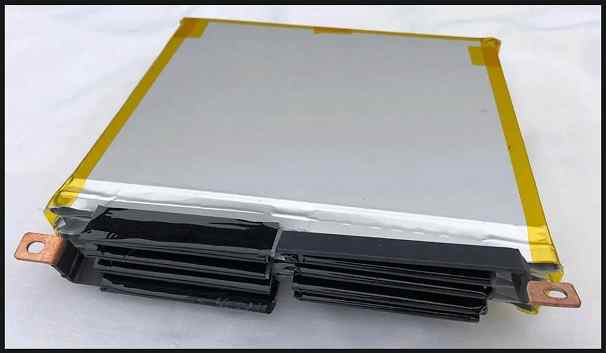

The team led by Professor Mohammad Asadi has created a new solid electrolyte that combines a polymer with ceramic, a common formula. Both have disadvantages when used separately but, when combined, bring together the high ionic conductivity of the ceramic and the stability and high interfacial connection of the polymer.

The new solid electrolyte is composed of a ceramic polyethylene oxide that allows the formation and decomposition of lithium dioxide to occur at high rates and room temperature, a first for a lithium-air battery. The design has the potential to store 1 kWh/kg (or even more), which is four times the energy density of the industry’s most advanced current lithium-ion batteries produced by Tesla. The team says it can further increase these numbers through optimization.

“The solid electrolyte contributes about 75% of the total energy density (solid electrolyte can make lithium-air batteries). This indicates that there is a lot of room for improvement because we believe that we can minimize its thickness without compromising performance, which would allow us to achieve a very high energy density,” says Asadi.

The new electrolyte shows high ionic conductivity and high stability in the charge and discharge cycle. According to the article published in Nature, in which the research is described, the new battery can withstand 1,000 cycles at high charge and discharge rates without degrading.

Related Post