Use buildings as giant renewable energy batteries? It will be possible thanks to cenospheres, a byproduct of coal

Use buildings as giant renewable energy batteries? It will be possible thanks to cenospheres, a byproduct of coal

By using cenospheres, researchers from the US NREL and the University of Alabama have discovered a technique to give different construction materials the strength they need to store backup energy.

Concerns have been raised in the energy sector by the recent COP28 accords, which set the lofty target of doubling the generation of renewable energy by 2030. Not in vain, international leaders declare that this is essential if we meet the target of maintaining the planet’s temperature increase at 1.5 ºC.

However, doubling the amount of renewable energy produced entails more than just installing more solar and wind turbines. Enhancing current technologies is crucial, as is maximizing the output of these two energy, which are erratic and reliant on weather patterns.

Take advantage of the full potential of renewable energies

Scientists and manufacturers in the energy industry have decided that the best way to ensure the usage of solar and wind energy generation is through backup batteries. Not in vain, they may produce so much energy when there is wind and sun that some of it is wasted since it cannot be stored.

So far, several solutions to this issue have been proposed. Ranging from the same batteries like lithium, hydrogen, salt water, or other kinds to technologies like pumped hydroelectricity or gravitational force.

Researchers at the University of Alabama have now developed a method that will enable energy to be stored in buildings similarly to a sizable backup battery, working with the US National Renewable Energy Laboratory (NREL).

Cenospheres are the key

The concept of using building materials as energy storage is not new. But up until recently, the tiny capsules meant for storing phase change materials meant for thermal energy storage often had insufficiently strong polymer shells.

Because of this, they were unsuitable for uses requiring great strength, including mixing them with concrete or other building materials.

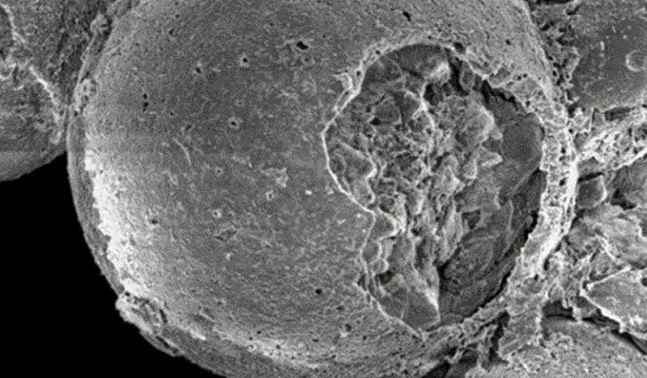

A “novel, nature-inspired method for applying a silica coating to the surface” of these microcapsules has been developed by the researchers to address this. Cenospheres, a byproduct of coal-fired power plants, make up the said coating.

This technology has “many important advantages over current approaches,” such as improved fire resistance and a “remarkable” improvement in the microcapsules’ thermal performance. Furthermore, it offers a great deal more resistance than earlier methods, making it possible to incorporate microcapsules “without a significant loss of resistance” in building structures.

According to Professor Jialai Wang of the University of Alabama’s Department of Civil, Construction, and Environmental Engineering, buildings may function as distributed energy storage units by integrating these materials into their HVAC (heating, ventilation, and air conditioning) systems.

That makes it possible to store extra energy produced during times of high renewable output for use at a later time, whether during times of low renewable production or increased demand.

These devices can also serve as buffers to lessen variations in the supply and demand of energy, providing stability to the electrical grid. Similarly, during emergencies or grid disruptions, buildings outfitted with these systems can serve as dependable sources of electricity.

What are cenospheres

The cenosphere is an air- or inert-gas-filled, hollow, lightweight, inert sphere composed mostly of silica and alumina. It is created as a byproduct of burning coal in thermal power plants. These cenospheres are unique because of the following:

- Light: The apparent densities of them vary from 0.35 to 0.45 g/cm^.

- Round: They make it easier to apply and distribute the substance that includes them evenly, because of their sphericity.

- Acoustic attenuation: sound waves are reflected and absorbed by them.

- Mechanical resistance: in paints, ceramics, asphalt, and concrete, they strengthen the substrate’s mechanical resistance.

- Refractoriness: foundries employ them for flame retardants and coatings that can withstand high temperatures.

- Thermal reflectivity: because of their poor thermal conductivity, they disperse heat.

- A hardness of 5–6 Mohs and inert.

Cenospheres are used to lighten a variety of materials, including plastics, rubbers, resins, refractories, and cement. They also offer advantages to the system to which they are incorporated, such as decreased weight, increased resistance, and enhanced fluidity.

They are utilized in low-density cement, paints, mortars, acoustic panels, pavements, and external insulation systems in the building industry. In addition, they find use in recreation, energy, technology, automotive materials, polymers, and ceramics.

Related Post