Amprius completes the production certification process for its dominant silicon cells.

Amprius completes the production certification process for its dominant silicon cells.

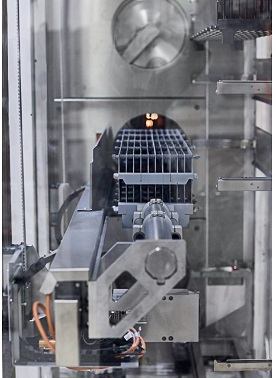

Amprius announced today that it has finished the certification procedure for its instrument for producing silicon nanowire anodes by deposition. This significant achievement represents a critical first step in boosting the manufacturing capacity of a battery type that increases batteries’ energy density.

Recall that the silicon anode, or positive electrode, is the foundation of this battery. On paper, it can store ten times as much lithium as graphite, the most popular type of battery. The business reports statistics of 450 Wh/kg and 1150 Wh/L, with third-party validation of 500 Wh/kg and 1300 Wh/L. Moreover, even at large output levels, it accomplishes this with a higher degree of safety against thermal runaway.

The ability of this kind of battery to maintain output capacity even at low battery charge levels is another intriguing characteristic. According to the business, a pack can sustain a power density of 3,000 W/kg at a discharge depth of 30%, and at high loads, it can reach a maximum power density of 4,400 W/kg.

Amprius has been refining its anode production process so that it can start exporting the first cells to the manufacturers this year. The manufacturers will handle the process of testing and verification.

Manufacturers appear to be considering this possibility, as seen by the hanging of the sign that reads “Everything sold by 2024.”

Amprius can add the Centrotherm tool to the company’s current roll-to-roll systems after this certification procedure is finished. As a result, starting in 2024, SiMaxx exports can increase when Amprius increases production at the Fremont, California factory to 2 MWh annually or roughly a ten-fold increase in online capacity.

“This achievement represents a crucial step forward in expanding production capacity to address the growing need for our ultra-high energy cells in electric mobility applications,” stated Jon Bornstein, president of Amprius Labs.

Amprius has received support from industry partners like BAE Systems, whose president, Robert Davidson, stressed the significance of Amprius qualification progress, saying: “The availability of ultra-high energy cells is paramount to expand the operational capability of our PHASA-35 High Altitude Long Endurance (HALE) vehicle.” This support comes in addition to internal validation.

With a large lithium-ion accumulation capacity that boosts the anode capacity to 1,000 mAh/g compared to 372 mAh/g of conventional graphite anodes, the nanowire structure helps you better utilize the potential of this material. It also allows you to significantly reduce the size of this electrode, increasing the specific energy.

One of the goals would be to meet the demand from industries like aviation, where weight is a crucial component. Sector in which the leading silicon cells will be able to provide a low-weight, highly safe substitute, enabling the electrification of some local routes or enabling the development of others, like vertical takeoff systems.

Source- Amprius

Related Post