Why BYD’s Blade batteries are a revolution in the electric car industry

In 2020 without too much noise, the new BYD Blade batteries were presented. The Chinese manufacturer launched a new type of cell that combined a high energy density, and the safety and low cost of lithium-fluorophosphate cells. Technology has everything necessary to help transform the automotive and transport sector in more sustainable ways.

But what makes this design so special that even Tesla is installing them?

Several keys to these “blade-shaped” cells have made them one of the leading players in the sector and that is allowing BYD to quickly position itself at the forefront of electric car sales globally. A second place in 2022 will be the first position this year for sure.

BYD’s Blade battery Better than conventional lithium packs?

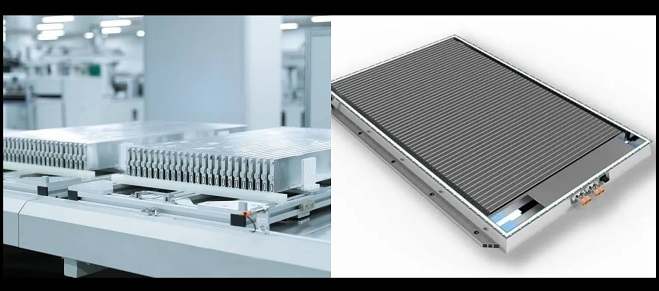

Like its name, the Blade battery is shaped like a blade with positive and negative terminals at each end. Each “blade” measures 38 inches long, 3.5 inches tall, and just 0.5 inches wide. These individual cells fit into an array and are then enclosed in a pack. A type of CTP (Cell to Pack) technology that maximizes the use of space by up to 50% compared to conventional cylindrical LFP batteries.

Thanks to this optimized structure, it is possible to improve the use of space, increasing the volumetric density by 30%. In terms of energy density, we are faced with an interesting 140 Wh/kg, the same figure exhibited by the majority of NCM-type batteries currently used by manufacturers, which in practice means minimizing the biggest drawback of LFP cells.

In addition, security is reinforced in multiple aspects. Starting with the fact that each Blade cell provides structural integrity to the pack, which allows for a more robust and safer system while offering a better weight/power ratio.

They are also safer against unforeseen events, such as accidents. And it is that as we have seen on several occasions, an accident or even an internal failure while stopped can cause the battery to burn with results in complex work for the fire brigade. Although it is not dangerous for the occupants, since the fire may need much more time to start than in a combustion model, it can be much more complex to extinguish.

In this regard, one of the advantages offered by Blade batteries is the use of lithium iron phosphate (LFP) for the cathode material. A material that offers greater security against thermal runaway thanks to a more stable chemistry, even at temperatures as high as 500 degrees.

BYD’s Blade battery has also passed the industry’s most demanding test, which includes the drilling of a nail to prove that the battery would not catch fire in the event of a short circuit. The surface temperatures of other batteries rose high enough to explode, but the BYD battery remained at a temperature of 30-60 degrees Celsius at all times, without external damage or fire.

Another extreme test the battery passed was when a 46-ton truck ran over it and it remained intact with no smoke, fire, leaks, or even deformation. BYD stated that the same battery was perfect and ready to be re-installed in a vehicle.

In addition, BYD has subjected these cells to other extreme resistance tests, such as being crushed, bent, or heated in an oven at 300°C and overloaded by 260%. None of these tests resulted in a fire or explosion.

Despite this, it is not to say that the batteries are indestructible we have seen some fires in BYD electric cars in China. At least 11 cases are known between 2020 and 2022, and almost all are related to a single model, the Han.

Something that indicates that there may be a problem with this particular model is that in a case in which a BYD Han caught fire after a crash test. Subsequently, BYD released a press release indicating that the car was using a coolant not authorized by the brand.

BYD’s Blade battery, now also in Tesla

The benefits of this battery go beyond BYD itself, and its main partner at the top of the electric car sales charts, Tesla, has also begun installing them in its cars.

At the moment only in the Model Y Standard that leaves the Berlin plant, but it is to be hoped that if production allows it, it will be extended to the Model 3/Y that leaves the China plant.

Some packs will also have a lower cost, which has also been estimated at 30% less than the current LFP cells, a factor that is possibly the key to the launch of the Tesla Model 2, the most economical model of the Americans, but also before for the arrival of BYD’s own cheapest proposal, the Seagull, which we will see on the market this year with a price below 10,000 euros in China.

Related Post