The importance of modular batteries and why the industry is against them

The presentation a few weeks ago of the Spanish brand of electric cars Liux has once again put on the table the practical and economic interest of modular batteries.

A new brand of electric cars was created in Spain and officially presented a few weeks ago. Based on the prototype of his first model, the Animal, Liux showed some interesting ideas that would be applied to his entire range of vehicles. Beyond the feasibility of his project and the opinions it has created among experts, his solution to use modular batteries has reopened an interesting debate on how to build electric cars.

Of all the components that are part of an electric car, there is one that is crucial and whose failure compromises all the others. The battery is not only the most expensive element of all those that compose it, but it is also the most susceptible to failure. Currently, an electric vehicle has a limited useful life to that of its battery. That can suffer an unpredictable failure that forces its replacement, with the economic burden that it implies, or degrade so much that its capacity is no longer sufficient for use in an electric car.

The most expensive and delicate component of an electric vehicle is also responsible for limiting or extending its useful life. Apart from technical reasons related to vehicle development and manufacturing processes, this does not seem like the ideal situation.

The advantages of modular batteries

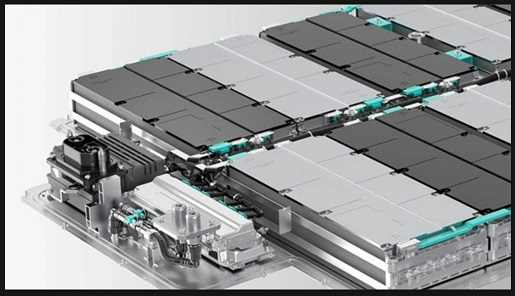

A conventional battery is made up of basic cells, which in turn are assembled into modules and are finally packaged inside the casing. That is the usual architecture that is used the most at the moment. But this division into modules does not make them modular batteries since once joined and no longer be separated easily.

When a battery pack has a problem with one or more cells, the only solution is to try to replace the faulty modules. In addition to assuming an expensive and slow intervention, many experts believe this option only delays the reappearance of the same problem. The correct solution is to replace the entire battery which is depending on the size and costs up to 20,000 euros.

If the batteries were modular, the defective module would simply have to be repaired which also allows the vehicle to continue working with the rest without having to remain paralyzed in a workshop. It would also prevent you from stopping in the middle of the road at the time of the breakdown. Modular battery packs also reduce repair costs. When there is no choice but to replace a complete module, its price will be much lower than that of changing the complete battery.

A modular battery also offers advantages in terms of recharging. Depending on the autonomy required, the owner could decide not to charge any of the modules and even alternate charging each one of them. That reduces, or at least distributes, the charge and discharge cycles and increases the useful battery life.

Finally, manufacturing a specific battery for each model significantly increases development and manufacturing costs and reduces the economy of scale. This drawback has been solved with the creation of dedicated electrical platforms that allow the use of the same components in a wide range of vehicles of various sizes.

The industry goes another way

The current industry trend is against modular batteries. The CTP (cell to pack) packaging which does without the intermediate modules in which the cells are grouped and the structural batteries, which are part of the chassis, are far from allowing modularity.

With these methods, the industry tries to increase energy density without connection systems and racks. More space for the cells means a greater amount of active material and greater autonomy.

However, these techniques should only be used when you are certain that the battery will outlast the car. But this, today, is not so. This way of building will scrap a vehicle when its battery fails or is out of warranty.

The battery-swapping solution

A compromise solution that is arriving from China is swappable batteries. In this case, there are two options. One is to reduce the purchase price of the car, which does not include the battery, in exchange for a monthly fee for the use of the exchange system. The other, acquiring it in property, only facilitates the replacement of the battery, but it does not prevent the cost of changing one for another from being very high.

So with the technology available today, it seems smarter to go for modular battery packs like the ones Liux proposes.

Liux’s idea

Liux has designed its products around a minimum of two and a maximum of four battery modules, each with a capacity of 23 kWh: 46 kWh in two-module vehicles and 92 kWh in four-module vehicles. With them, the company’s future electric car with greater autonomy will reach 600 kilometers, that is, 150 km per module, without taking into account weight reductions when scaling its size.

The Spanish startup says it will build its cars in the same way that BMW built the i3 and i8: a procedure similar to mounting the body on a frame. The main difference is that the chassis has three beams instead of just two: the third, in the middle, is the support that supports the small modular battery packs that are placed in rows of two and parallel.

Related Post