These batteries with a dominant silicon anode have 50% more energy density and are already in production

These batteries with a dominant silicon anode have 50% more energy density and are already in production

Ionblox is an American startup that has just announced the successful closing of a new financing phase for the development of batteries that want to revolutionize the market. Some cells are designed for applications such as electric cars or vertical takeoff vehicles, which stand out for their high energy density, their thermal safety, and for being already in a pre-production phase.

The company has just announced its second closing of the financing round has allowed them to raise another 32 million dollars in an operation that has included initial investors, such as the development company of flying electric vehicles Lilium and also Applied Ventures. A list that has now been joined by other names such as Temasek and Catalus Capital.

The company has confirmed that it will use the funding raised to scale up the production of its cells, which are being manufactured on an experimental line commissioned in 2022 in addition to improving the technology, and developing high-power cells for electric aviation and cell prototypes.

The key to the design of the batteries with lithium cells with a dominant silicon anode pre-lit.

Ionblox says its batteries achieve up to 50% more energy density than conventional lithium cells, five times the power output, and an extremely fast charge that can take an average battery capacity from 0 to 80% in 10 minutes.

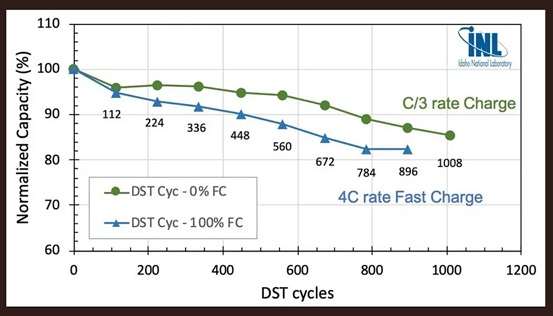

Some cells whose performance they indicate has been verified by the Idaho National Laboratory, dependent on the United States Department of Energy. The company is also partnering with semiconductor equipment giant Applied Materials.

It is currently producing its large format bag cells of up to 50 Ah in its pilot line in Fremont, California, from where they send its samples to manufacturers such as General Motors, Ford, or Chrysler, who are looking for the formula to bring recharge times closer to the of refueling a combustion car.

What is a Pre-Lithium Dominant Silicon Anode Lithium Battery?

These batteries use silicon as the main material for the anode. In conventional lithium-ion batteries, the anode is made of graphite but in Ionblox batteries, a pre-lithiated predominantly silicon anode material is created by combining silicon with a small amount of lithium.

The use of silicon in the anode allows you to enjoy several benefits over graphite, including a greater lithium storage capacity. That allows an increase in energy and volumetric density to be achieved, so more energy can be stored in a smaller size, resulting in lighter and more compact batteries.

Prelithiated silicon anodes are more stable during charge and discharge compared to graphite anodes, reducing the risk of lithium metal buildup, extending battery life, which is placed in current designs in more than 1,500 cycles at 3C, and also drastically reduces the chances of fire or short circuits. Something key in technologies such as vertical takeoff electric vehicles.

However, pre-lit silicon anodes also have some disadvantages, such as lower conductivity and a tendency to undergo mechanical degradation during repeated charge and discharge cycles, which can reduce overall battery performance and efficiency.

Now, Ionblox hopes that with the latest rounds of funding, they can speed up the work to finish developing a technology that for many experts, maybe the most feasible and fastest way to improve the capacities of lithium batteries without having to wait for future designs like the solid electrolyte and other distant promises.

Related Post