They create a new technology in Japan to recharge the old batteries of electric cars.

Toyota’s research team creates innovative solutions for old electric car batteries, giving them new life.

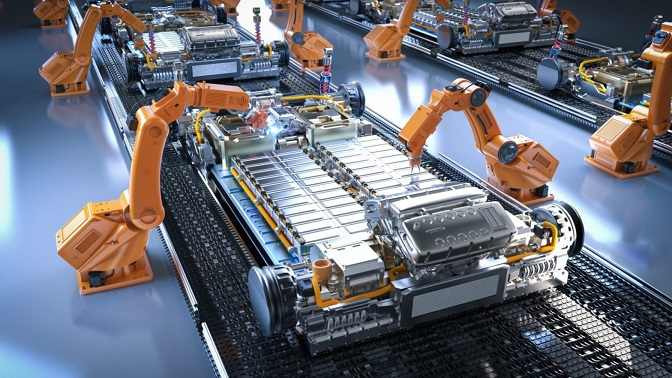

A new technological innovation has the potential to completely change the way lithium-ion batteries are treated and introduced in Japan, specifically under the Toyota brand. This technology had the potential to be one of the most successful recycling techniques by recovering them nearly entirely.

This Japanese car manufacturer’s research team has created a way to revive lithium-ion batteries, nearly returning their original charging capacity. This procedure, which includes injecting chemicals into batteries to prolong their life, may be essential in resolving the issue of battery demand as the number of electric vehicles on the road rises in the upcoming years.

New life for electric car batteries

These days, it’s nearly hard to avoid using lithium-ion batteries because they power so many different gadgets, including electric cars, computers, and mobile phones. But over time, these batteries degrade, losing their capacity to hold onto energy and shortening their usable life.

By introducing positively charged lithium ions and negatively charged electrons into the system, a Toyota research team has discovered a way to stop this degradation process. This method not only extends the batteries’ useful life and increases their capacity, but it also makes it easy to recycle.

Lithium naphthalene, a chemical highly effective in restoring up to 80% of the battery’s original capacity, is the basis of the technique. Additionally, laboratory tests have demonstrated that this effect endures over time, guaranteeing that the batteries will keep their full capacity for up to 100 cycles of charging and discharging.

Not effective for all batteries

Researchers caution that while this method may be revolutionary, it is not always successful, particularly where batteries have structural damage. Furthermore, additional long-term research will be required to completely comprehend the impact of chemical injection side effects on treated battery performance.

Despite these difficulties, the novel approach minimizes the number of processes required, which lessens the environmental impact and away with the need for disassembly, making it a significant advancement in the recycling of electric car batteries. With funding from both public and private institutions, Toyota researchers have already filed for a patent on this technology.

This new method could provide a promising way to prolong the life of lithium-ion batteries, which would lessen the need for new battery production and not be eco-friendly. This technology could be important in creating a more sustainable future, as the demand for electric vehicles is predicted to rise in the upcoming years.

Related Post