Revolutionizing EVs: The Game-Changing Lithium Ceramic Battery from Europe

The future of electric vehicles (EVs) hinges on breakthroughs in battery technology. While Asian companies have traditionally dominated this space, a German innovation center, FEV, in collaboration with Taiwanese partner ProLogium, is rewriting the narrative. Together, they’ve developed a groundbreaking lithium ceramic battery (LLCB) that promises to redefine EV performance, safety, and sustainability.

This new technology boasts remarkable features, including ultra-fast charging, higher energy density, reduced weight, and enhanced safety—all while being environmentally friendly. Let’s explore how this promising battery technology could revolutionize the EV industry and pave the way for a more sustainable future.

The Need for a Battery Revolution

As EV adoption accelerates globally, the demand for batteries that combine high energy density, rapid charging, and affordability has intensified. Current lithium-ion batteries, while efficient, have limitations such as safety risks, dependency on rare materials, and relatively slow charging times.

Innovators around the world are racing to address these challenges, experimenting with emerging technologies like sodium batteries, solid-state batteries, and silicon anodes. However, the LLCB developed by FEV and ProLogium aims to combine the best of these advancements into a single, cohesive solution, offering an exciting glimpse into the future of EV batteries.

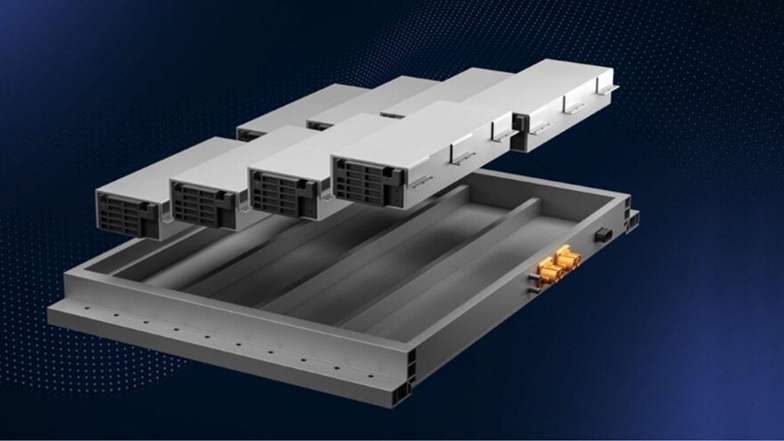

A Look Inside the LLCB Battery

At the heart of the LLCB battery are two revolutionary innovations:

- A 100% Silicon Anode:

- Traditional lithium-ion batteries rely on graphite anodes, but the LLCB replaces this with silicon.

- Silicon offers a tenfold increase in energy density, translating to greater autonomy for EVs.

- Additionally, this shift reduces dependency on China, which controls the majority of the global graphite supply. Silicon, by contrast, is more abundant and widely available.

- Solid-State Electrolyte:

- The “ceramic” in the lithium ceramic battery refers to its solid-state electrolyte.

- This technology enhances battery safety by minimizing risks such as thermal runaway, short circuits, and electrolyte leaks.

- Solid-state batteries also improve charging efficiency, enabling ultra-fast charging times without compromising safety.

Performance That Sets New Standards

The combination of a silicon anode and solid-state electrolyte enables the LLCB battery to achieve exceptional performance metrics:

- Ultra-Fast Charging:

According to FEV, the battery can charge from 5% to 60% in just 5 minutes, providing enough energy for a 300-kilometer trip. Extending the charge to 80% takes only 2 additional minutes, a dramatic improvement over conventional batteries. - Impressive Autonomy:

With its enhanced energy density, the LLCB battery can deliver up to 1,000 kilometers of range, depending on the vehicle segment and intended use. - Weight Reduction:

The battery’s innovative design can reduce the weight of an EV by up to 300 kilograms, contributing to improved efficiency and performance.

Advantages Beyond Performance

The LLCB battery isn’t just about impressive numbers—it also brings a host of practical benefits for both manufacturers and drivers:

- Cost-Effective Design:

- The battery’s thin, compact design simplifies integration into various EV models, reducing manufacturing costs.

- Its modular structure makes it easier to maintain, as slimmer cells can be replaced or recycled individually, further lowering maintenance expenses.

- Enhanced Safety:

- Solid-state technology eliminates many of the safety concerns associated with traditional lithium-ion batteries, such as the risk of fire or explosion during charging.

- Sustainability:

- The use of silicon and a recyclable modular design aligns with the growing push for environmentally friendly technologies in the automotive sector.

A Leap Forward in Charging Times

Charging infrastructure and speed have been major bottlenecks for widespread EV adoption. The LLCB battery addresses this by drastically reducing charging times, a critical factor for drivers who rely on their vehicles for long-distance travel or daily commutes.

- With the ability to charge from 5% to 80% in just 8 minutes, this battery reduces charging times by more than 80% compared to current technologies.

- Drivers no longer need to spend extended periods at charging stations, bringing EV convenience closer to the refueling experience of traditional internal combustion vehicles.

Impact on the Automotive Industry

The potential applications of the LLCB battery are vast, and its introduction could disrupt the automotive industry in several ways:

- Expanded Market Reach:

- With greater autonomy and faster charging, EVs equipped with LLCB batteries will appeal to a broader range of consumers, including those hesitant to switch from traditional vehicles.

- Lower Manufacturing Costs:

- The simplified integration process and reduced reliance on graphite could lower production costs for automakers, potentially making EVs more affordable for consumers.

- Acceleration of EV Adoption:

- By addressing common consumer concerns such as range anxiety and long charging times, the LLCB battery could serve as a catalyst for mainstream EV adoption.

What Sets FEV and ProLogium Apart?

While many companies are working on next-generation batteries, FEV and ProLogium stand out for their ability to combine cutting-edge technologies into a single, high-performance solution.

- German Engineering Excellence:

FEV brings decades of expertise in automotive innovation, ensuring that the LLCB battery meets the rigorous demands of modern EVs. - Taiwanese Technological Expertise:

ProLogium contributes its solid-state battery expertise, which has been instrumental in realizing the LLCB’s potential.

Together, these companies are challenging the dominance of Asian battery manufacturers and demonstrating Europe’s capacity for innovation in the EV space.

While the LLCB battery shows immense promise, its success will depend on scaling production and ensuring affordability. As with any emerging technology, widespread adoption requires overcoming challenges such as manufacturing complexity, supply chain logistics, and initial costs.

However, the potential rewards are enormous. If FEV and ProLogium can bring the LLCB battery to market at scale, it could mark a turning point in the EV industry, enabling vehicles that are safer, faster to charge, and capable of longer journeys—all while being more sustainable.

The lithium ceramic battery developed by FEV and ProLogium represents a significant leap forward in EV technology. With its groundbreaking combination of a 100% silicon anode and solid-state electrolyte, this battery addresses many of the challenges that have limited EV adoption, offering a compelling vision of what the future holds.

From ultra-fast charging to extended autonomy and enhanced safety, the LLCB battery promises to deliver the performance and convenience that EV enthusiasts have been waiting for. As this technology moves closer to commercialization, it’s poised to transform not only the way we think about electric vehicles but also the broader landscape of sustainable transportation.

For manufacturers, drivers, and the planet, the LLCB battery could be the breakthrough we’ve all been waiting for.

Related Post