This German start-up converts your gasoline car into an electric one in just one day.

The world of electric car conversions is something that has been around for a while. However, the way this German start-up, called e-Revolt, carries out these transformations.

To give you an idea, the traditional (and expected) conversions of a car with a combustion engine to a 100% electric one usually take vehicles with quite a few years behind them, and the transformations typically take between 2-weeks and six months, depending on the difficulty of the job.

E-Revolt reduces times considerably: it claims to take, on average, a single day to carry out this conversion, which is based on more modern vehicles. This is precisely where the ‘trick’ of the German company lies since its conversion processes are limited to a series of specific brands and models.

Up to 42 different models fall within the range of work of these very fast e-Revolt conversions, such as the Volkswagen Golf used as a model, Seat León, Audi A3… Three models, in this case, which, as you know, share a platform.

The key to e-Revolt’s work is using a one-size-fits-all kit that is easily installed by taking advantage of the common supports offered by the chassis of the combustion cars in question. This kit includes the battery, which provides an electric range of between 250 and 300 kilometers, although the Germans claim to be working to improve this performance.

And the price? The transformation using this electrical kit costs between 12,000 and 15,000 euros, which also includes the ‘extra’ digitization of the interior, incorporating a screen with an additional multimedia system where you can see the performance of the battery. E-Revolt also guarantees the study of the process of converting to an electric vehicle from other different models.

«It’s a production; you have to think about how you can do it faster and easier. But this only works if you have a lot of volumes because you have to put in a lot of work and money upfront to develop all of this. You can save time and money later. But that’s the difference: you have to have a serious solution,” says Rolf Behling, CEO of e-Revolt.

How e-Revolt carries out the conversion to an electric car

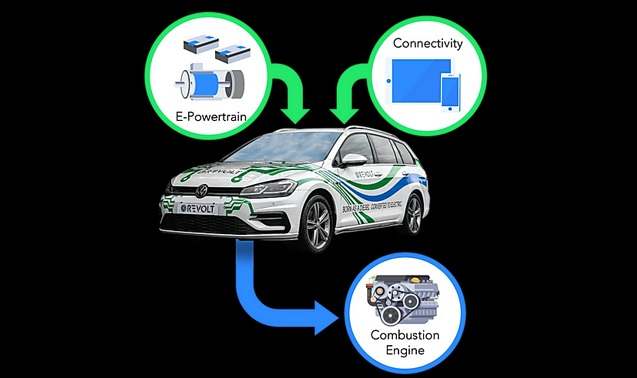

The German start-up uses patented frame, motor, and battery technology, ensuring that the conversion carried out in certified workshops in its network is legal and compliant. An innovative, scalable, fast workflow that also guarantees the circular economy of the components used.

First, e-Revolt and the workshop in question will carefully evaluate in advance whether the conversion can be carried out safely, including a physical inspection. Once accepted, the old engine and any unnecessary components will first be removed. According to the German company, it is committed to giving a second life to these components so they can be “reused in other applications or responsible recycling.”

E-Revolt ensures the supply of all the components necessary for the conversion process to the certified workshop: the “Plug and Play” frame, the e-CAN module, screws, hoses, and the electric motor and battery. For the conversion, a “rigorous and standardized” process will be followed, complying with all legal regulations related to the registration of road vehicles,” the company says on its website.

The dashboard will be digitalized, incorporating a new screen with a multimedia system from which to access the functions of the new electric vehicle, such as charge control, remaining autonomy, navigation, connected services, etc.

Finally, it is carried out with quality control by an independent agency, which will guarantee “compliance with legal regulations and the highest safety standards.”

Related Post