Electric vehicles (EVs) are continually evolving, with automakers pushing the boundaries of innovation. One recent breakthrough comes from Mercedes-Benz, which has unveiled an advanced power converter technology that promises to revolutionize how EV battery packs function. Highlighted during the Mercedes Future Experience event in Stuttgart, this programmable micro-converter represents a leap forward in efficiency, modularity, and battery management.

Let’s dive into this groundbreaking innovation and what it means for the future of EVs.

What is the Micro-Converter, and How Does It Work?

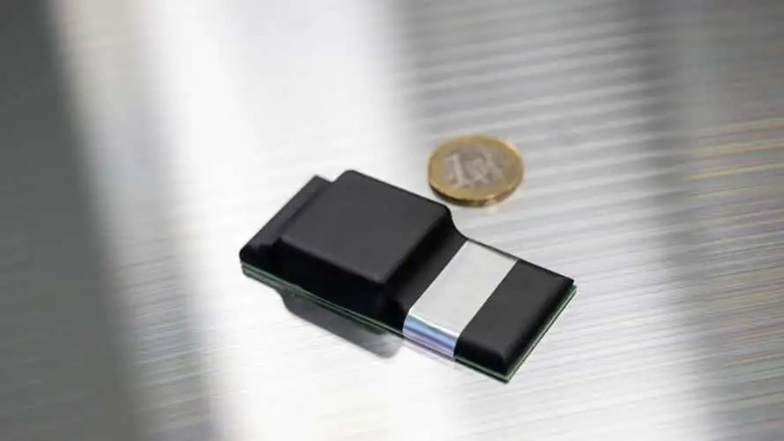

The innovative micro-converter Mercedes-Benz is developing can be embedded at the cell level within the battery pack. This device allows precise, wireless control of individual cell pairs, unlocking significant advancements in battery management. Traditionally, EV batteries connect cells in series, meaning issues with one cell can impact the entire battery pack. Mercedes’ new approach requires cells to be connected in parallel, enabling unparalleled control and efficiency.

Key Features of the Micro-Converter Technology:

- Wireless Control:

Each cell pair is individually adjustable via wireless commands, allowing for a tailored charging approach to each cell’s unique needs. - Damage Isolation:

The system can isolate damaged cells without affecting the rest of the battery pack, significantly improving reliability and longevity. - Enhanced Battery Health Monitoring:

By offering granular data on each cell’s performance, the technology enables accurate battery diagnostics, pinpointing problem areas without guesswork. - Constant Voltage Output:

Unlike traditional EV batteries, whose voltage varies based on the state of charge, this micro-converter keeps the pack’s voltage steady at 800 volts, enhancing performance and consistency.

Benefits for Electric Vehicles

Mercedes-Benz’s micro-converter technology addresses several long-standing challenges in EV battery design. Here are some of the most significant benefits:

1. Modular Battery Design

The new system makes it easier to create modular battery packs. Manufacturers can design packs that are more space-efficient, cost-effective, and versatile, allowing for greater standardization across vehicle models.

2. Mixed Battery Chemistries

During the event, Mercedes-Benz CTO Markus Schäfer hinted at the possibility of combining different battery chemistries, such as lithium iron phosphate (LFP) and nickel manganese cobalt (NMC), in a single pack. This “mix and match” approach could harness the strengths of both types:

| Battery Chemistry | Advantages | Disadvantages |

|---|---|---|

| LFP (Lithium Iron Phosphate) | Better thermal stability, affordable, less degradation with frequent fast charging | Lower energy density, shorter range |

| NMC (Nickel Manganese Cobalt) | Higher energy density, ideal for long-range EVs | Expensive, more prone to degradation with fast charging |

By integrating both chemistries, automakers could achieve a balance between range, durability, and cost.

3. Cost Efficiency

The modular approach facilitated by the micro-converter can reduce production costs. Standardized battery components allow automakers to scale up manufacturing, minimizing waste and enhancing flexibility in design.

4. Improved Efficiency and Longevity

By controlling charge distribution more precisely and isolating problem cells, the technology could extend battery life. It also optimizes energy delivery, reducing losses and improving overall performance.

What Does Constant Voltage Mean for EVs?

One of the standout features of this innovation is the ability to maintain a constant 800-volt output, regardless of the battery’s state of charge. This consistency offers numerous advantages:

- Faster Charging: High-voltage systems enable quicker energy transfer, reducing charging times significantly.

- Enhanced Compatibility: A steady output voltage simplifies integration with other vehicle components, such as inverters and motors.

- Predictable Performance: Drivers experience consistent vehicle performance, even as the battery drains.

Challenges and Future Prospects

Although the technology holds immense promise, it’s still in its early stages. Schäfer acknowledged that integrating multiple chemistries and refining the micro-converter system requires further testing. Key challenges include:

- Manufacturing Complexity: Producing batteries with embedded micro-converters adds new layers to the production process.

- Scalability: Achieving mass production while keeping costs low will be crucial for widespread adoption.

- Durability Testing: Real-world performance under diverse conditions needs validation before commercialization.

Despite these hurdles, Mercedes-Benz’s vision for the future of EV batteries is bold and transformative.

How Does This Compare to Current EV Battery Technology?

Traditional Battery Packs vs. Mercedes’ Micro-Converter System

| Aspect | Traditional Battery Packs | Mercedes’ Micro-Converter System |

|---|---|---|

| Cell Connectivity | Cells connected in series, affecting entire pack if one fails | Cells connected in parallel, isolating issues |

| Voltage Control | Voltage varies with state of charge | Constant 800V output |

| Health Monitoring | Generalized diagnostics | Individual cell-level monitoring |

| Energy Utilization | Less efficient | Optimized charge distribution |

| Cost Efficiency | Higher costs due to lack of modularity | Lower costs with modular design |

Revolutionizing EVs with Mixed Chemistries

Combining LFP and NMC cells in a single battery pack could address several pain points in the EV industry. For example, LFP batteries excel in affordability and durability, making them ideal for city cars or frequent fast charging. Meanwhile, NMC batteries’ higher energy density makes them better suited for long-distance travel. By mixing these chemistries, automakers can cater to diverse use cases without compromising on quality or performance.

Mercedes-Benz: Leading the EV Revolution

The introduction of programmable micro-converters underscores Mercedes-Benz’s commitment to innovation and sustainability. As the EV market grows increasingly competitive, breakthroughs like these will help the brand stand out.

Potential Real-World Applications:

- Affordable EVs: Cost-efficient modular batteries could make EVs accessible to a broader audience.

- Longer Lifespans: Improved diagnostics and isolated cell control reduce the need for early replacements.

- Versatile Fleet Options: Modular designs allow automakers to tailor battery packs for different vehicle segments, from city commuters to luxury SUVs.

Mercedes-Benz’s micro-converter technology represents a significant step forward in EV battery design. With the promise of better efficiency, improved safety, and mixed chemistry integration, this innovation could reshape how batteries are built and used in electric vehicles. While the technology is still in its infancy, its potential to revolutionize the EV industry is clear.

As the automotive world transitions toward electrification, innovations like these will play a pivotal role in ensuring sustainable and efficient mobility for the future. Mercedes-Benz is not just keeping pace with the industry—it’s leading the charge.

Related Post